Digital Billboard Truck: Boost Your Campaign with Mobile Ads

Picture this: you take the flash and spectacle of a Times Square billboard, slap it on the back of a truck, and send it wherever

Before you even think about ordering steel or pouring a concrete foundation, the real work of installing a billboard begins. It all comes down to two things that will make or break your project: site selection and permitting.

Get these right, and you're on your way to a profitable sign. Get them wrong, and you’re looking at a world of headaches.

The perfect spot is completely useless if you can't legally build on it. This initial phase is where the dream meets reality—a mix of street-smart analysis, logistical planning, and cutting through red tape. It's where you find out if your project is actually viable.

A lot of newcomers underestimate just how complex this is. They see a great piece of land on a busy highway and think they've struck gold. But the truth is, a web of zoning laws, traffic patterns, and local ordinances stands between you and that "perfect" spot. One wrong move here can lead to costly delays, flat-out rejections, or even legal battles.

A good site survey isn't just about finding a busy road; it's about finding the right busy road. It's so much more than just counting cars. You need to dig deep into the factors that actually make a billboard location profitable.

When you're out there scouting, here's what you should be laser-focused on:

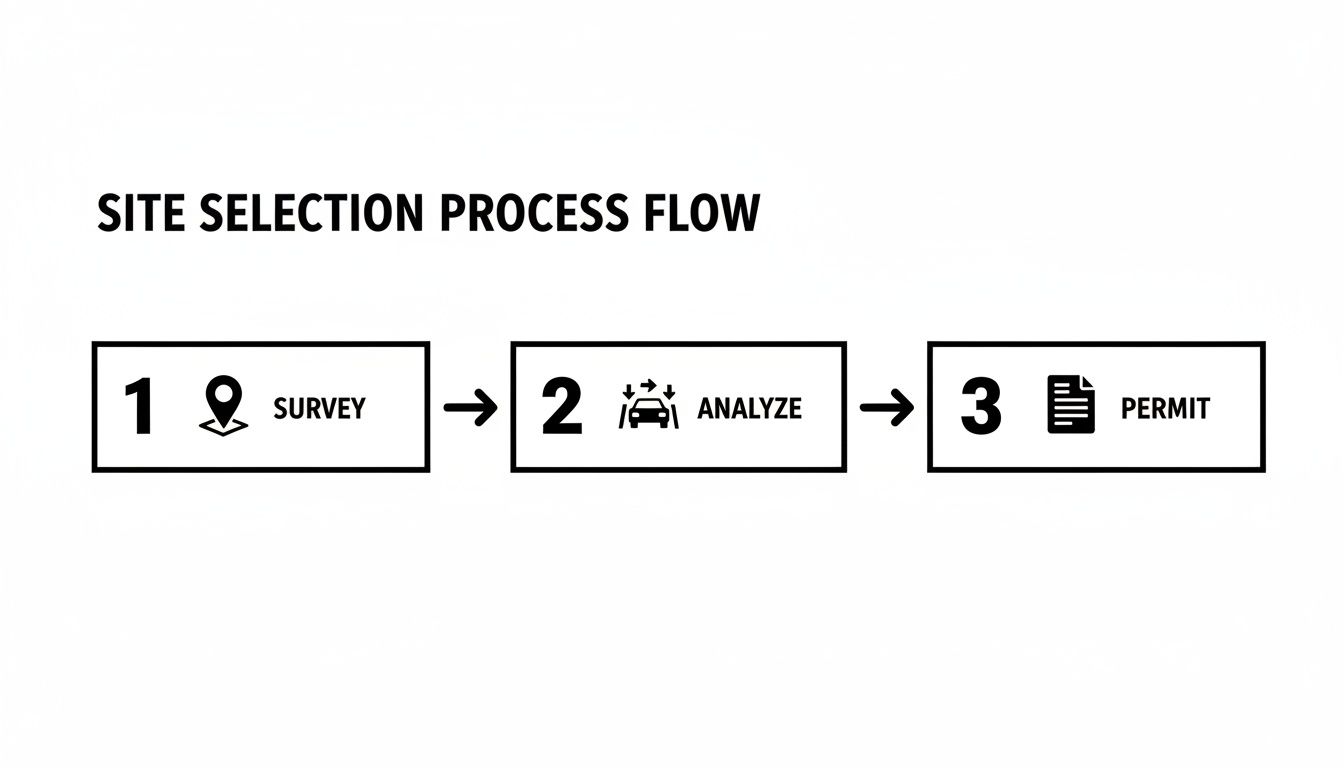

This simple flowchart breaks down the basic workflow to get you started.

As you can see, it's a logical progression. You survey, you analyze what you've found, and then you dive into the permitting process. Each step builds on the last, setting a solid foundation for your entire project.

Okay, so you’ve found a few promising locations. Now the real fun begins: the paperwork. Navigating the maze of permits and zoning laws is, without a doubt, the toughest part of installing a billboard. Every town, city, and county has its own rulebook, and state regulations often pile on another layer of complexity.

Key Takeaway: Never, ever assume a property is good to go based on location alone. Get down to the local planning department and verify the zoning regulations before you spend a dime on a lease or purchase.

Your first stop should be the city or county planning department. Ask to see their zoning maps. These will tell you if a property is zoned for commercial, industrial, or residential use. As a rule, billboards are only allowed in commercial and industrial zones. Trying to put one in a residential area is a guaranteed dead end.

And it doesn't stop there. If your spot is visible from a state or federal highway, you'll almost certainly need a stamp of approval from the state's Department of Transportation (DOT), like Caltrans in California. They have their own strict rules about spacing, size, and how close a sign can be to the road. This often means you're chasing two sets of approvals—one local, one state.

The outdoor advertising industry is huge and complex. Recent data shows there were nearly 15,000 businesses in the U.S. billboard sector, and all those local rules mean costs and timelines can vary wildly from one place to the next. You can dig into more of this data on the U.S. outdoor advertising market at IBISWorld.

Once you've navigated the maze of permits and secured your spot, the project shifts from paperwork to actual groundwork. This is where your billboard finally starts to take shape, beginning with the single most critical component you'll never see: the foundation.

A massive steel structure topped with a vibrant LED display is only as good as the base holding it up. Skimping on structural engineering isn't just a bad idea—it's a recipe for disaster. A professional engineer isn't just a recommendation; they're an essential partner who ensures your structure can handle everything from hurricane-force winds to shifting soil for decades.

Before a single shovel hits the dirt, a thorough geotechnical analysis of the soil is a must. This isn't just about digging a hole; it's a scientific assessment of the ground's composition, density, and overall stability. The findings from this report directly dictate how the foundation needs to be designed.

A site with loose, sandy soil, for example, is going to demand a much deeper and wider foundation than one sitting on dense clay or solid bedrock. The engineer takes this data, along with local weather patterns, to run crucial wind load calculations. These numbers determine the immense forces the billboard will have to endure during severe storms, making sure the structure won't bend, buckle, or worse.

A standard 14×48 foot billboard can face wind forces equivalent to the weight of several cars during a major storm. The foundation is the sole defense against these powerful, invisible pressures.

All this engineering work culminates in a detailed blueprint for the foundation. It specifies everything—the depth, the shape, and exactly how much reinforced steel (rebar) is needed. Precision here is everything.

With the engineering plans locked in, the construction phase kicks off. Heavy machinery carves out the earth to the exact dimensions laid out in the blueprints. After that, a complex cage of rebar is assembled and lowered into the hole. This steel skeleton is what will give the concrete its incredible tensile strength.

When it comes to the pour, bringing in the right team is critical for stability and longevity. Most projects of this scale rely on commercial foundation concrete specialists who know the specific demands of these massive structures.

The concrete pour itself is a carefully choreographed event. Multiple trucks often arrive in succession to fill the entire form in one continuous go, which prevents weak spots or "cold joints" from forming. Once poured, the concrete has to cure for several weeks to reach its required compressive strength before any steel can be erected on top of it.

Choosing the right foundation isn't a one-size-fits-all decision. The geotechnical report and engineering plans will point you in the right direction, but it helps to understand the most common options.

| Foundation Type | Best For | Avg. Cost Per Footing | Installation Time |

|---|---|---|---|

| Monopole Caisson | Standard highway billboards, areas with stable soil | $15,000 – $30,000 | 3-5 days + cure time |

| Spread Footing | Areas with weaker soil, requiring wider load distribution | $20,000 – $40,000 | 5-7 days + cure time |

| Multi-Leg Pylons | Very large displays or unique structural requirements | Varies Significantly | Varies Significantly |

Each type serves a specific purpose, balancing cost, installation time, and the demands of the site itself. The monopole caisson is the workhorse of the industry, but challenging soil conditions often make a spread footing the smarter, safer choice.

While the foundation is curing, the steel components for the billboard structure are typically being fabricated off-site. The most common design you see today is the monopole—a single, large-diameter steel column.

Monopoles are popular for their clean aesthetic and relatively small footprint on the ground. The steel used is incredibly robust and gets treated with corrosion-resistant coatings to handle decades of rain, snow, and sun. Every weld and every bolt is specified by the engineer to guarantee the structure's integrity, all the way from the baseplate to the display frame. It's this meticulous attention to detail that ensures the safety and longevity of your investment.

With the foundation poured and the steel in place, we move from raw construction to the technical heart of the project. A modern digital billboard is really just a massive, high-performance computer screen. Its brain and circulatory system are the electrical and data connections, and getting this part right is what turns a static structure into a dynamic, money-making machine.

This phase is a team sport, requiring tight collaboration with licensed electricians and your local utility provider. You can't just run an extension cord out to these things; they demand a serious, stable, commercial-grade power feed to operate reliably day in and day out.

First things first: you need to calculate the total power draw of your LED display. This isn’t a ballpark guess. The exact wattage hinges on the sign's size, pixel pitch, and maximum brightness settings. A high-resolution 14×48 foot screen, for instance, running at full blast on a sunny day can pull a surprising amount of electricity, often needing its own dedicated commercial service.

With your power requirements calculated, it's time to get the local utility company involved. This process can sometimes drag on for weeks or even months, so start this conversation early. They'll figure out the closest connection point and determine if a new transformer is needed to handle the load.

Pro Tip: When you’re planning the power connection, always think about the future. If there's even a slight chance you might add accent lighting or other powered gear later, request a service with enough amperage from the get-go. Upgrading later is a much bigger—and more expensive—headache.

A huge part of connecting the billboard involves getting the wiring from the grid to the structure. Learning the basics of underground utility trenching for electrical lines will give you a major leg up. Trenching is almost always the way to go, as it keeps your vital cables safe from weather, mowers, and potential vandalism.

An LED billboard is a hefty investment in sensitive electronics, and it’s a magnet for electrical trouble. Without the right protections, a single power surge from a nearby lightning strike or a grid hiccup could fry thousands of dollars worth of components in a blink.

Robust protection isn't optional; it's mandatory. Here’s what a proper setup looks like:

Power gets the sign lit up, but data brings it to life. To manage content, monitor the display's health, and run diagnostics from your office, you need a rock-solid data connection. The best choice really comes down to the billboard's location and how you plan to operate it.

There are three main ways to get it connected, each with its own pros and cons.

| Connectivity Method | Ideal Use Case | Pros | Cons |

|---|---|---|---|

| Fiber Optic Cable | Urban or suburban sites with existing fiber lines | Blazing fast, super reliable, highly secure | Can be expensive to install; not available everywhere |

| Cellular (4G/5G) | Remote or rural locations, or where trenching is a pain | Flexible, deploys quickly, widely available | Monthly data fees, potential for signal dead zones |

| Point-to-Point WiFi | Multiple signs located near a central office | Low ongoing costs, fast connection | Needs a clear line of sight, can be prone to interference |

For most modern digital outdoor signage, a cellular connection hits the sweet spot between flexibility, cost, and reliability. The data needed to upload new ad creatives is actually pretty small, so a 4G or 5G plan is usually a very cost-effective way to manage a whole network of signs from one place. At the end of the day, a stable connection is the key to keeping your content fresh and ensuring your billboard is always working for you.

Once the steel structure is reaching for the sky, the most visually rewarding part of the job begins. This is where a skeleton of metal transforms into a vibrant, functional display. The process involves meticulously mounting the individual LED modules, or cabinets, onto the frame.

Precision is the name of the game here. Even a tiny misalignment can create noticeable seams or gaps in the final image, completely ruining the professional look. Installers rely on specialized lifting equipment and laser alignment tools to get every single cabinet perfectly flush with its neighbors. The goal is to create one massive, seamless digital canvas.

The assembly usually happens in sections. Rather than hoisting one panel at a time, crews will lift and attach several pre-assembled blocks of modules together, carefully connecting data and power ribbon cables as they go. It’s a much more efficient approach.

Think of it like putting together an enormous, high-tech puzzle hundreds of feet in the air. Each piece has to fit perfectly while also communicating flawlessly with the others to create a uniform, brilliant image across the billboard’s entire face.

Getting this right is a big deal in a massive global industry. The outdoor advertising market is worth tens of billions, with some reports projecting it could grow to over USD 60 billion by 2030. You can dig into more detailed projections and learn about the outdoor advertising market to grasp the scale. This financial reality is exactly why durable, long-lasting installations are so critical for a solid return on investment.

A digital billboard’s greatest enemy isn't the competition—it's the weather. Rain, snow, humidity, and dust are relentless in their attempts to get inside and mess with the sensitive electronics. Honestly, effective weatherproofing is the single most important factor in your sign’s lifespan.

This goes way beyond just having a sealed outer case. It’s a multi-layered defense strategy designed to protect every last connection and component.

An Ingress Protection (IP) rating is the industry standard for measuring how well an enclosure holds up against solids and liquids. For outdoor billboards, you need a rating of IP65 or higher. That means it's completely dust-tight and can handle water jets from any direction. Don't settle for less.

Weatherproofing isn’t just about keeping water out; it's also about managing the internal climate. LEDs generate a surprising amount of heat, and direct summer sun can push internal temperatures to damaging levels. On the flip side, frigid winter weather can harm components if the sign can't keep itself warm.

A well-engineered ventilation system is crucial. This usually involves a mix of high-powered, temperature-controlled fans and strategically placed vents. The system pulls in cooler air, circulates it over the hot components, and pushes the warm air out.

In extremely cold climates, some systems even include small heating elements to keep the electronics within their safe operating temperature range. This obsessive attention to detail is what ensures your investment performs reliably, no matter what the forecast says.

The steel is up, the power is live, and the last LED module has been locked into place. Your structure finally looks like a billboard, but the real magic is about to begin. This next step, commissioning, is where we turn that dormant grid of hardware into a living, breathing, money-making display.

Think of commissioning as the ultimate quality control marathon. It’s a deep dive into every pixel, wire, and line of code to guarantee your sign performs flawlessly from day one. Skipping or rushing this part is a recipe for disaster—dead pixels, blotchy brightness, and connection drops that lead to angry advertisers and expensive emergency service calls. This is where a professional-grade asset is separated from a very expensive headache.

First things first, we need to dial in the display's visuals. It’s a delicate process to make sure the billboard looks absolutely brilliant whether it's battling the glare of the noon sun or glowing in the dead of night.

The main goal here is achieving perfect color and brightness uniformity across every inch of the screen. Our technicians use specialized light meters and software to measure the output of each individual module, making tiny adjustments until a solid white screen is perfectly seamless. No patches, no lines, just one massive, uniform canvas.

Next up is brightness. An LED sign blasting at 100% brightness after dark isn't just a nuisance; it’s a legitimate hazard to drivers. That's where an ambient light sensor comes in. We install and calibrate it to automatically manage the display's output.

This isn't just about following rules; it's about being a good neighbor and ensuring public safety.

Before a single ad graces the screen, every component has to survive a full-scale diagnostic gauntlet. This is where we proactively hunt down any hardware gremlins that might have appeared during shipping or the installation itself.

The process involves pushing a series of test patterns—solid red, green, blue, white, and black—to the display. Technicians then meticulously scan the entire face of the billboard, searching for:

It’s infinitely easier to spot and swap out a faulty module now than it is after the billboard is already running live campaigns.

Expert Insight: Never, ever skip the "aging test." We run the billboard at full brightness, displaying a solid white screen for anywhere from 24 to 72 hours straight. This stress test is designed to force any weak or borderline components to fail now, so we can replace them before they become a real-world problem for you.

Once the hardware gets a clean bill of health, we shift our focus to the brains of the operation: the software. Your Content Management System (CMS) is mission control, letting you schedule ads, upload creative, and check the billboard’s vital signs from anywhere with an internet connection.

During commissioning, our team installs and configures the CMS, connects it to the display's controller, and locks in a stable, secure remote connection. Whether you're using cellular, fiber, or Wi-Fi, we test it rigorously. The ability to troubleshoot, reboot the system, or push new content without rolling a truck is the key to running a profitable billboard. Seeing this all come together on projects like a 10×30 UHD billboard installation in San Antonio really drives home how critical that seamless software link is.

The very last step is a complete end-to-end workflow test. We upload a sample ad, schedule it to play, and watch to confirm it runs exactly as it should. Once that final check is passed, your billboard isn't just built—it's officially commissioned, fully optimized, and ready to go live.

A successful billboard project doesn't end the moment your display flickers to life. In fact, that’s just the beginning. The real, long-term value of your investment hinges on what happens next: proactive maintenance and smart financial planning. Thinking about upkeep from day one is what separates a short-lived headache from a profitable, long-term asset.

Let's get practical about the numbers and the ongoing work required. A well-planned budget and a solid maintenance schedule are your best tools for maximizing uptime and protecting your bottom line for years to come.

Before we even get to maintenance, let's nail down a realistic initial budget. The price of the LED display is obviously a major line item, but it's far from the only one. Surprise expenses are the enemy of profitability, so a detailed cost breakdown is absolutely essential.

Your budget needs to account for every single phase of the project:

Understanding the full financial picture is the first step. For a deeper dive into what drives these numbers, our guide on the factors influencing outdoor LED sign cost is a great resource to explore.

It's also crucial to understand the broader market context when you're planning this kind of investment. The billboard industry is going through a massive digital transformation. Static vinyl signs are rapidly being replaced by dynamic LED displays that are perfect for programmatic advertising. This trend is fueling some serious market growth.

The global digital billboards market was valued at roughly USD 42.6 billion and is projected to reach about USD 112.5 billion by 2034, showing a compound annual growth rate of approximately 10.2%. North America is a huge player here, holding over 40% of this market. This shift makes installing a billboard with modern digital capabilities a truly forward-thinking investment.

Once your billboard is up and running, "set it and forget it" is not an option. A proactive maintenance schedule is your best defense against unexpected—and costly—downtime. This isn't about waiting for something to break; it's about routine check-ups to keep everything in peak condition.

A solid schedule should include:

Key Takeaway: Think of maintenance as a form of insurance. A small, consistent investment in upkeep will save you from much larger, more expensive emergency repairs down the road and keep your ad revenue flowing without interruption.

Your relationship with your LED sign provider shouldn't end after the check clears. A strong warranty is a critical part of your purchase, but you need to understand exactly what it covers. Most standard warranties cover parts, but you should always clarify if labor and travel for service calls are included.

Beyond the warranty period, you need a long-term service plan. Who are you going to call when a power supply fails five years from now? Having a relationship with a reliable service provider, or understanding how to source replacement parts directly from the manufacturer, is crucial.

Planning for this ensures that when a component inevitably fails, you have a clear, cost-effective plan to get your billboard back online as quickly as possible, minimizing lost revenue and protecting the health of your valuable asset.

At Smart LED Inc., we believe a successful installation is just the start of our partnership. We provide robust warranties and ongoing support to ensure your investment performs for years. Ready to build a billboard that lasts? Explore our high-durability outdoor LED solutions today.

Picture this: you take the flash and spectacle of a Times Square billboard, slap it on the back of a truck, and send it wherever

A wall of TV screens is exactly what it sounds like: a big, impressive display made by tiling multiple TVs together so they act like

Picking the right displays for shows can feel like a high-stakes guessing game. Get it right, and you create an immersive world that captivates your

"*" indicates required fields